Fennel processing plants and lines.

Complete lines for processing fennel, from the campaign to the packaging.

Bulltec offers a plant that can preserve the perfect condition of the vegetable during all stages of processing.

BULLTEC SOLUTIONS FOR FENNEL PROCESSING

The Bulltec processing lines for fennel are complete and can be implemented with the section dedicated to the cleaning and cutting of tufts and product roots.

1) ELECTRONIC CUP SIZER:

Bulltec has reserved a project completely dedicated to the processing of fennel with a patented system for transporting the cups, by belt, and no longer by chain, using them for the calibration of the product. Both weight and size sensing systems can be integrated to this machine.

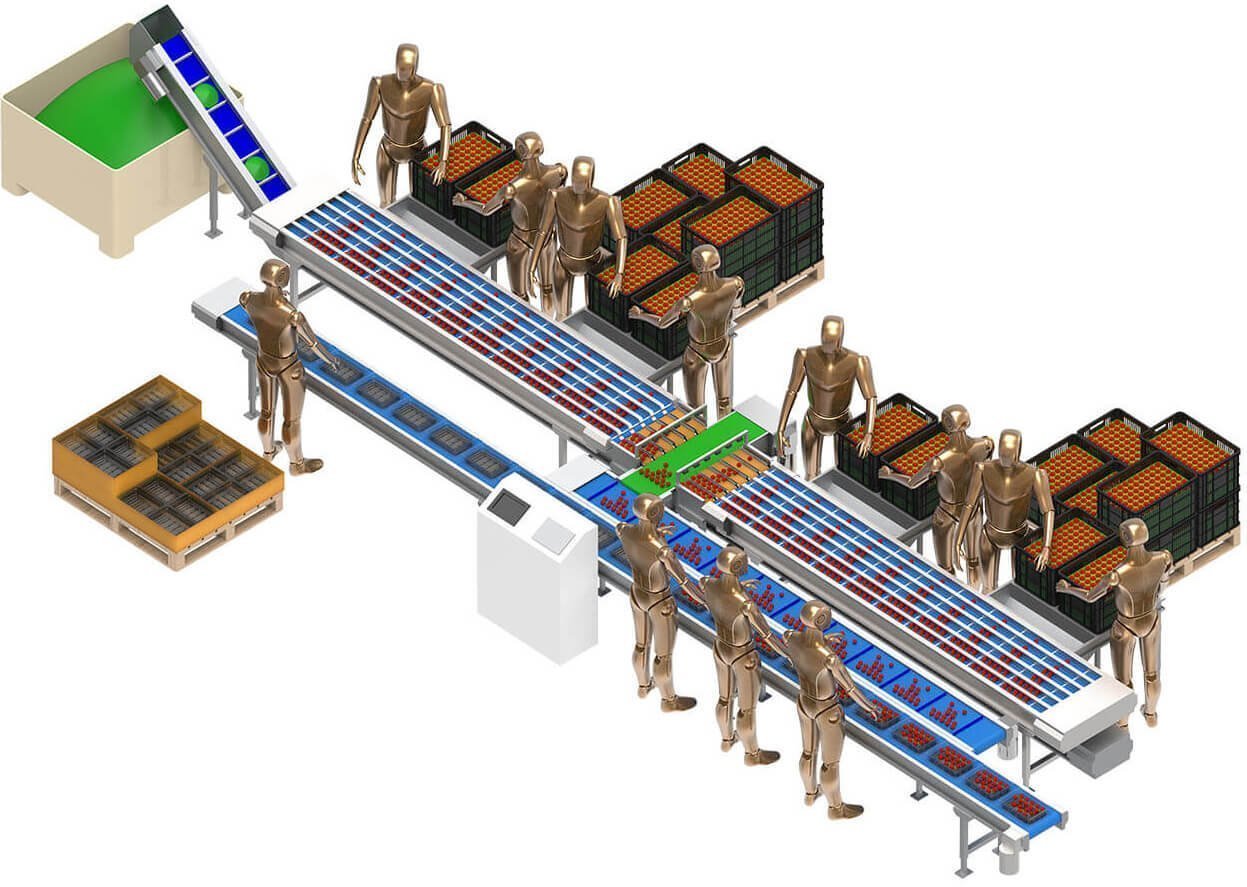

2) ELECTRONIC CALIBRATION BY WEIGHT AND SIZE:

Through a patented system, you can calibrate your fennel by size (length diameter) and by weight.

Both solutions can be installed on the same line.

This will give you a wide range of possibilities with a single solution.

* in figure:

2-CHANNEL LINE FOR CALIBRATING BY SIZE OF VEGETABLES,

6 ELECTRONIC OUTPUTS

+1 MECHANICAL OUTPUT

Learn more about our calibrators!

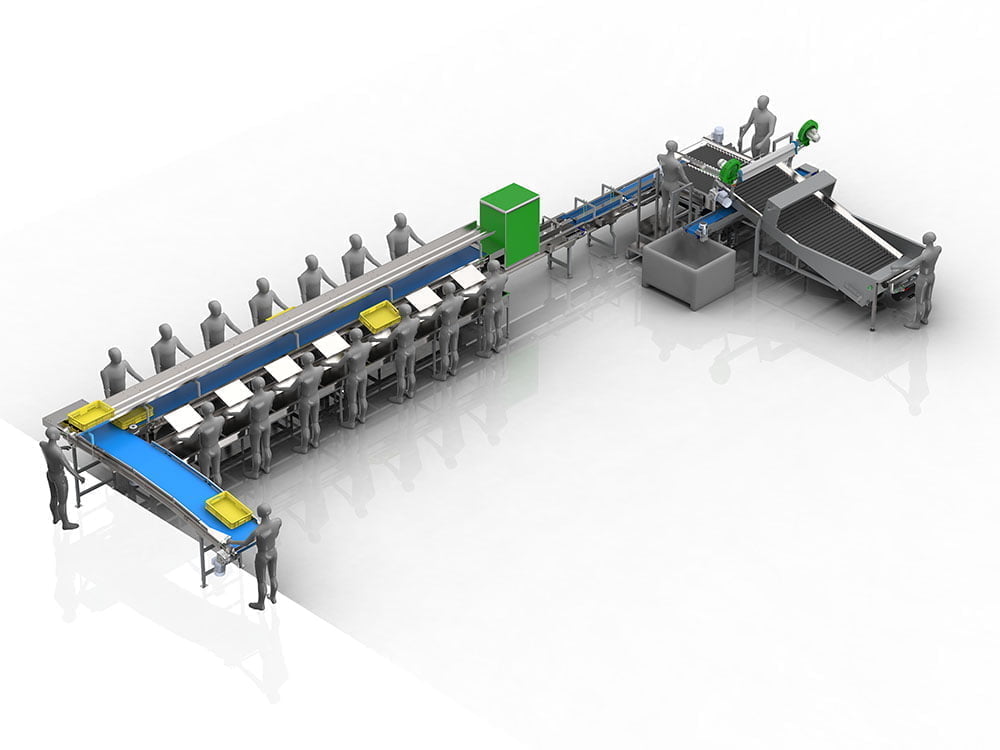

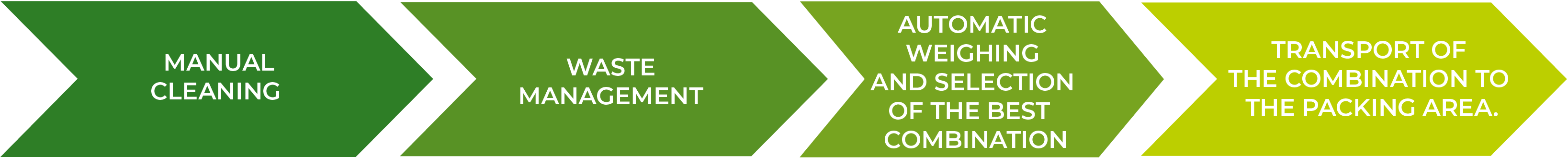

3) COMBINED WEIGHT PLANT:

A new complete solution from Bulltec for packaging fennel in trays and baskets with a guaranteed minimum weight.

A specially designed plant to enable you to automate the process of:

Entrusting only the last step of the process to manual labor will allow for better product configuration in the tray.

Customize your tray by minimum weight and number of pieces.

THE ADVANTAGES OF USING A BULLTEC LINE

Efficient Calibration

Thanks to Bulltec’s dedicated fabrication SOFTWARE, we can offer millimeter-precision dimension calibration and weight calibration with gram accuracy.

Versatility of use

Process different types of vegetables on the same machine, with the ability to calibrate very different items by weight and size.

Simple Mechanics

Product conveyor belt and adjustable pneumatic actuators for product ejection ensure simplicity in line handling.